Description

Description:

- Polyethylene container 800 – 1000 l with smooth inner surface

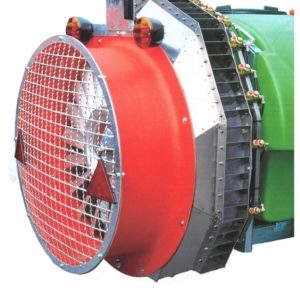

- INOX crossflow / oblique-flow fan case with adjustable air deflector plates

- Fan case with air output (power) approx. 45.000 cfm/h

- Individual nozzle control and feed

- Nozzle bodies with 2 or 3 output (application) options and anti-drip membranes

- Two-speed transmission

- Transmission remote control

- Centrifugal clutch

- Piston diaphragm (membrane) pump 106 l – 120 l plastic coated

- Hydraulic stirrer

- Line filter (pressure filter) with central cleaning (automatic backwash when with electric-switch-box)

- Suction filter

- Distributor with pressure fine-tuning on the tractor

- Lighting system

- Chassis hot-dip galvanized

Additional equipment:

- Coupling device

- Material container with mixing device, packaging cleaning, powder and liquid suction

- Material container GLOBALGAP – system with lockable lid, mixing device, packaging cleaning, powder and liquid suction

- To select: Electric-switch-box with manometer, electric-switch-box with digital display and velocimeter, control monitor or spraying control computer

- Establishment drift-reducing nozzles

- Part-width section control

- Electronic tank filling

- Flowmeter output

- System flushing – electrically connected

- Oil hydraulic brake system

- Rotating nozzle (barrel cleaner)

- INOX powder mixer with cleaning nozzles

- Device for watering saplings (young trees)